In today's rapidly evolving industrial landscape, the significance of fluid control systems is more pronounced than ever. A critical component within these systems is the Duo-Check Valve, which plays a pivotal role in ensuring the safe and efficient operation of various applications, from water treatment processes to petrochemical facilities. According to a report by MarketsandMarkets, the global market for flow control devices, including Duo-Check Valves, is projected to reach USD 12.67 billion by 2025, reflecting a robust annual growth rate of 4.5%. This growth underscores the increasing reliance on advanced fluid management technologies in diverse sectors.

Industry expert Dr. Jonathan Carter, a leading authority in fluid dynamics, emphasizes the impact of Duo-Check Valves on operational reliability, stating, "The use of Duo-Check Valves not only enhances the integrity of fluid systems but also minimizes the risk of backflow, which can lead to costly downtimes and safety hazards." His insights shed light on the operational advantages these valves offer, such as reduced maintenance costs and improved system longevity. As industries strive for greater efficiency and safety, the Duo-Check Valve has emerged as a cornerstone of modern fluid control solutions, underscoring its importance in contemporary engineering practices.

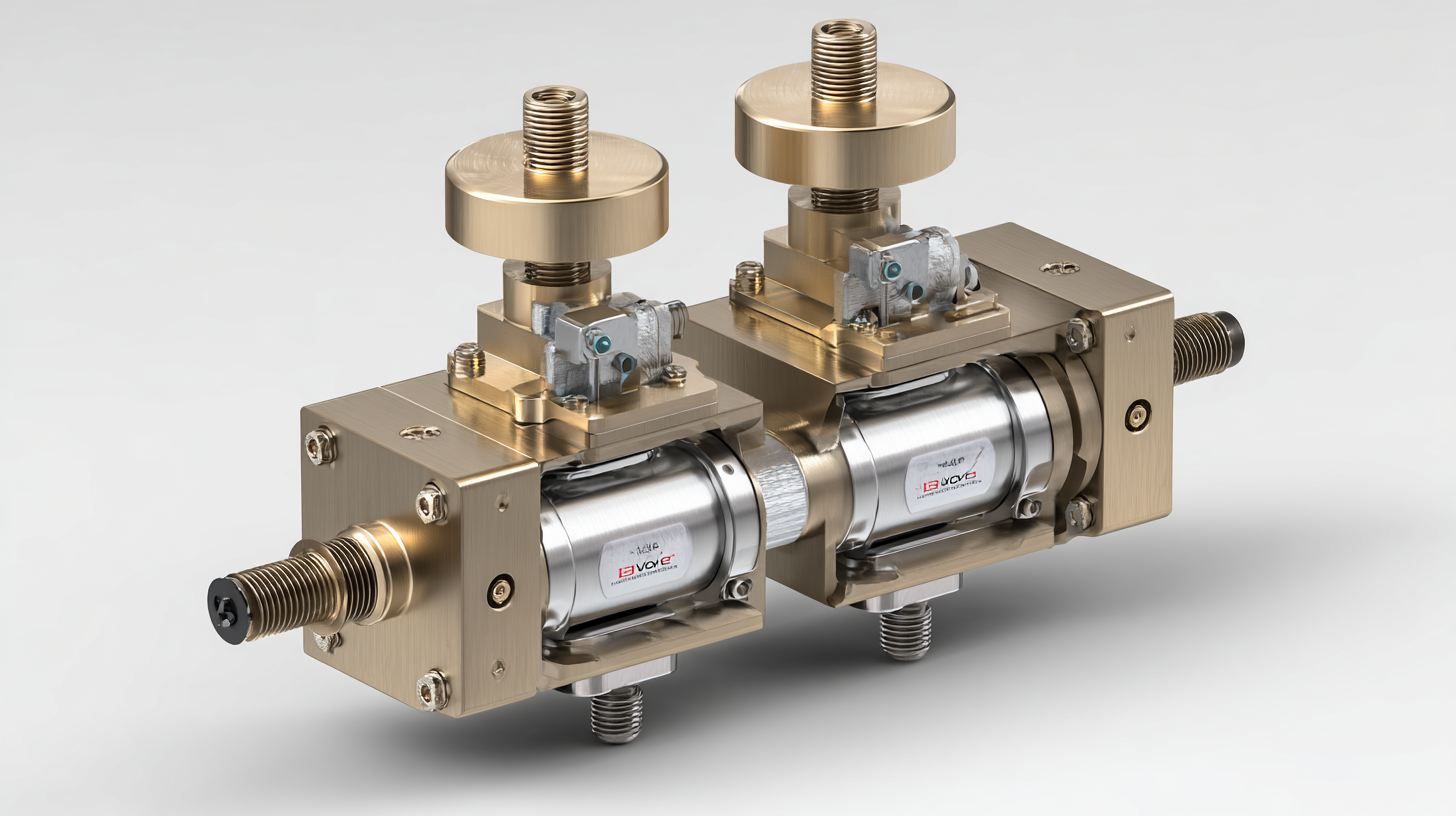

Duo-check valves play a pivotal role in enhancing the efficiency of modern fluid control systems. These valves are specifically designed to prevent backflow, ensuring that fluids only move in the intended direction. By doing so, they maintain the integrity of the fluid system, minimize the risk of contamination, and protect critical components from potential damage caused by reverse flow. This proactive measure not only extends the lifespan of system elements but also optimizes overall performance.

Moreover, duo-check valves contribute significantly to energy savings within fluid control systems. By preventing reverse flow, these valves reduce the need for additional energy inputs to maintain pressure and flow rates. This efficiency translates into lower operational costs, making them an economical choice for various applications. Industries from manufacturing to HVAC systems benefit from their installation, as duo-check valves ensure reliability and operational continuity—critical factors in today’s fast-paced environment. Thus, their role in streamlining processes cannot be overstated, highlighting their essential function in contemporary fluid management.

Duo-check valves have emerged as a vital component in modern fluid control systems, offering numerous advantages over traditional valve designs. One significant benefit is their ability to prevent backflow effectively while maintaining a high flow rate. According to a report by the Fluid Control Association, duo-check valves can reduce pressure drops by up to 30% compared to conventional spring-loaded check valves, enhancing overall system efficiency. This is particularly crucial in industries such as oil and gas, where even minor inefficiencies can lead to substantial losses.

Another key advantage is their compact design, which allows for easier installation and maintenance. Traditional valves often require extensive space and complex setups, leading to increased installation time and costs. A study by the International Journal of Fluid Mechanics highlighted that duo-check valves can save installation costs by approximately 25%, making them an attractive option for engineers looking to optimize their fluid systems.

Tips: When selecting a duo-check valve, consider the specific fluid type and pressure requirements to ensure optimal performance. Additionally, regular maintenance and inspections can prevent potential failures, thereby extending the life of the valve and improving system reliability.

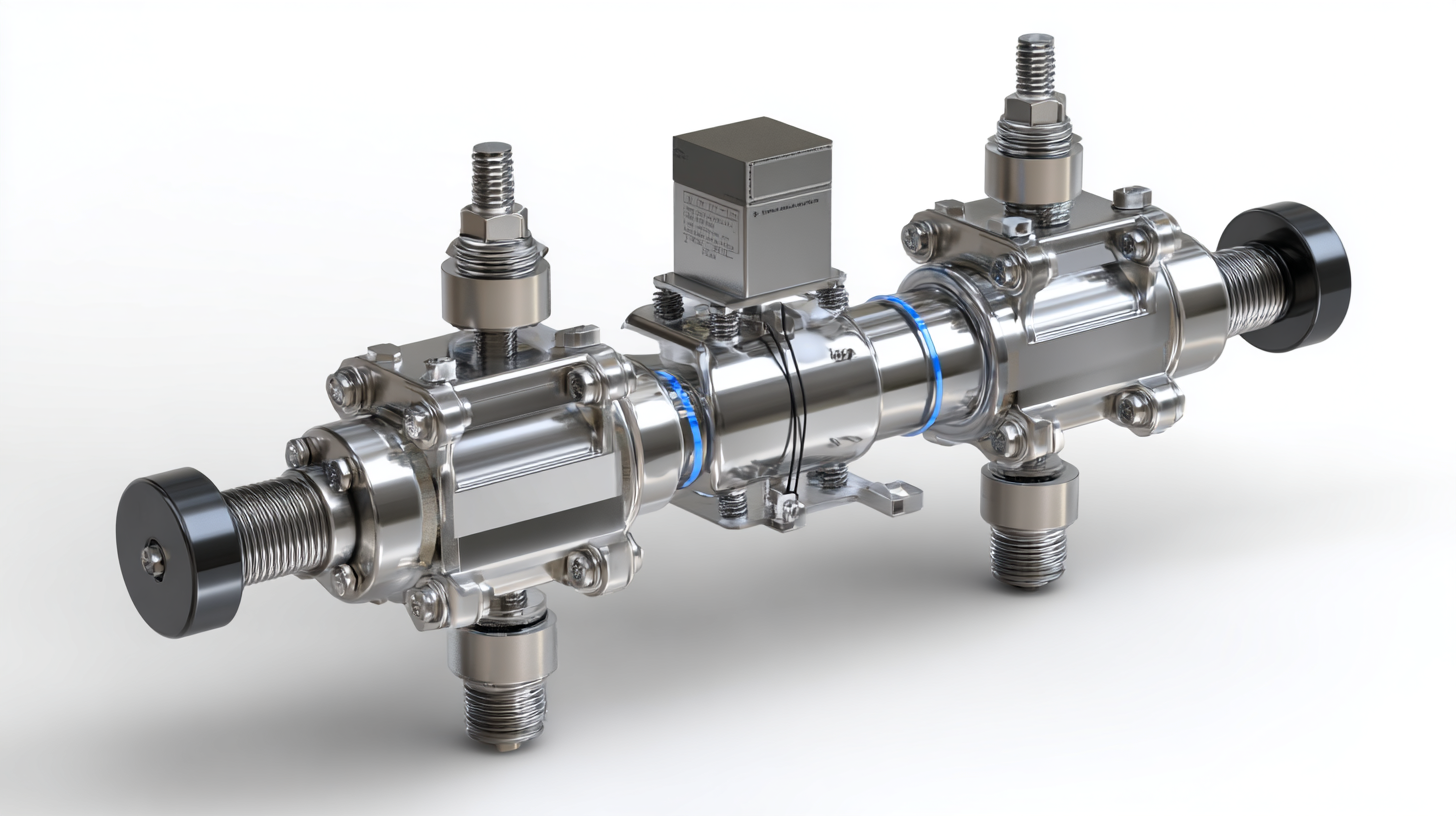

Duo-check valves are an integral component in modern fluid control systems, offering a reliable solution for preventing backflow and ensuring smooth operation across various industrial sectors. In the water treatment industry, duo-check valves play a crucial role in maintaining the purity of water by preventing contamination through reverse flow. These valves are equally vital in the oil and gas sector, where they safeguard pipelines from pressure fluctuations and potential leaks.

In the chemical processing field, duo-check valves assist in managing different fluid mixtures efficiently, ensuring that hazardous substances do not flow back into their respective systems. Their robust design also allows them to withstand extreme temperatures and pressures, making them suitable for high-stakes applications.

**Tips:** When selecting a duo-check valve, consider the specific requirements of your system, including flow rates and pressure conditions. Regular maintenance checks can help ensure optimal performance, preventing costly downtime. For sectors dealing with corrosive fluids, opt for materials specifically designed to resist chemical degradation, extending the valve's lifespan and reliability.

| Industry Sector | Application | Key Benefits | Common Specifications |

|---|---|---|---|

| Oil & Gas | Pipeline Isolation | Prevent backflow, reduce pressure surges | DN50-DN100, ANSI 150-300 |

| Water Treatment | Wastewater Management | Maintain flow direction, minimize spillage | DN80-DN200, PN10-PN16 |

| Chemical Processing | Chemical Transfer | Safety containment, leak prevention | DN25-DN150, Class 150 |

| Food & Beverage | Sanitary Processing | Prevent contamination, ensure hygiene | DN40-DN100, 3A Standards |

| HVAC Systems | Refrigerant Flow Control | Control gas flow, prevent back pressure | DN15-DN50, ISO Standards |

When selecting a duo-check valve for fluid control systems, understanding the critical factors that influence performance and reliability is paramount. Key considerations include the valve's material compatibility with the fluid being controlled, the required pressure rating, and the expected flow rate. According to industry reports, improperly selected valves can lead to significant inefficiencies, impacting system performance by up to 30% and resulting in increased operational costs.

In applications like shower systems, where precise temperature and flow control are essential, the choice of valve becomes even more crucial. The right duo-check valve can prevent backflow and ensure a steady flow rate, enhancing user experience and safety. A recent study highlighted that improper valve selection in residential plumbing systems could contribute to up to 15% of home water waste. By prioritizing compatibility with environmental factors and adhering to relevant industry standards, users can avoid costly mistakes and ensure optimal system functionality.

Maintaining optimal performance of duo-check valves is essential for ensuring efficiency in modern fluid control systems. Regular inspections should be conducted to identify any signs of wear or damage. Check for leaks, unusual noises, or vibrations that may indicate a malfunction. Implementing a routine maintenance schedule can help prolong the lifespan of the valves and prevent costly downtime.

Cleaning is another critical aspect of maintenance. Contaminants can accumulate within the valve, leading to restricted flow or complete blockage. Using suitable cleaning agents and methods, ensure the valves are free from debris. Lubrication of moving parts is also vital; it reduces friction and wear, contributing to smoother operation. Additionally, always follow the manufacturer's guidelines when performing maintenance tasks to avoid any potential damage.