In the quest for sustainable materials, Rubber Material has emerged as a frontrunner in innovative applications. Its versatility spans various industries, from construction to automotive. The ability to mold and adapt Rubber Material allows for creativity in design and function.

Consider the automotive industry, where Rubber Material is used in tires and seals. These components ensure safety and durability, contributing to improved performance. Yet, challenges remain. The environmental impact of rubber production raises questions. Are we doing enough to minimize waste?

Additionally, in the realm of consumer products, Rubber Material finds its way into everyday items. Think of kitchenware, footwear, and even electronics. These applications highlight rubber's utility but also reflect the need for ethical sourcing and recycling methods. As we explore the best uses of Rubber Material, we must confront these complexities. Exploring innovative applications can lead to breakthroughs, but not without reflection on our practices.

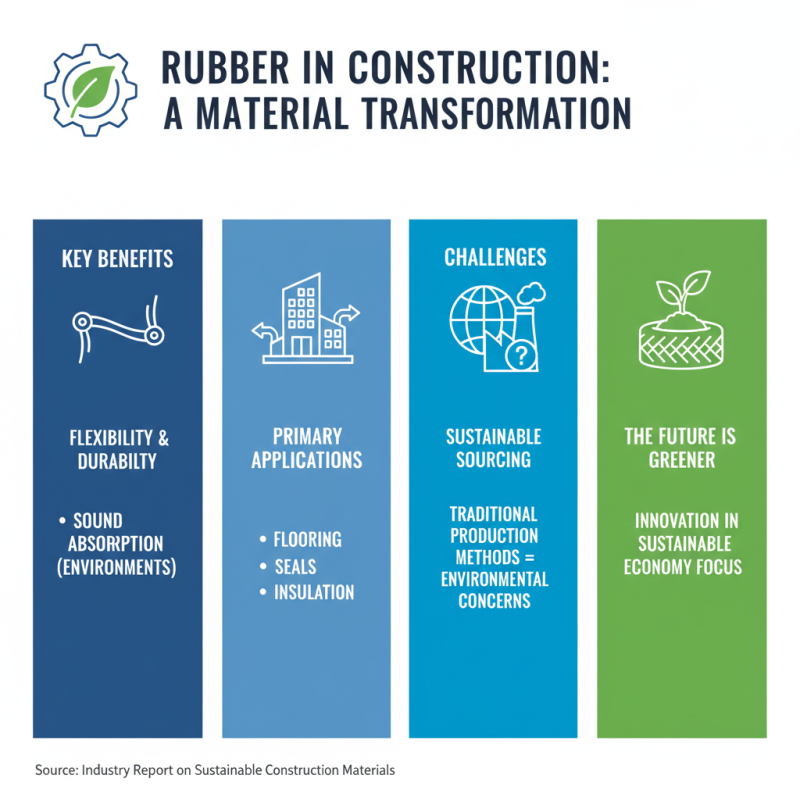

The construction industry is experiencing a transformation with the increasing use of rubber materials. These materials offer impressive flexibility and durability. Rubber can be integrated into various applications, such as flooring, seals, and insulation. Its ability to absorb sound makes it ideal for urban environments. Yet, challenges remain in sourcing sustainable rubber. Most rubber is still produced through traditional methods, raising environmental concerns.

In 2026, trends indicate a rise in recycled rubber use. Construction companies are exploring ways to repurpose rubber waste. This can lead to innovative products, like rubberized asphalt for roads. However, the technology has not fully matured. Some projects may face issues with consistency and performance. Contractors must remain cautious and test extensively before full-scale application.

Rubber's impact on construction design cannot be overlooked. It allows for creative and resilient structures. Buildings can incorporate rubber for better energy efficiency. Yet, integrating these materials requires thorough planning. Not all designs can successfully utilize rubber's properties. Project teams must adapt and innovate continuously, facing the imperfect realities of construction challenges.

Rubber composites are transforming the automotive industry in 2026. New formulations are making vehicles safer and more efficient. Lightweight rubber materials are crucial for electric cars. They help reduce overall vehicle weight while providing excellent durability. This balance is not easy to achieve. Testing and refinement are ongoing processes.

Innovations in rubber technology are also improving performance. Enhanced grip and weather resistance are vital for tire development. However, creating the perfect tread pattern remains a challenge. Engineers continually experiment to find the right balance. Each trial brings valuable insights, but results can be inconsistent.

Environmental considerations are driving change too. Sustainable rubber sources are becoming more important. Yet, integrating these materials without sacrificing quality is tricky. The industry must reflect on its practices. There is still a long way to go for a truly green auto sector.

| Application Area | Material Type | Innovative Feature | Benefits |

|---|---|---|---|

| Tire Manufacturing | Natural Rubber Composites | Enhanced grip and durability | Longer lifespan and better road performance |

| Vibration Dampening | Silicone Rubber Blends | Superior dampening properties | Reduced noise and vibration in vehicles |

| Seals and Gaskets | EPDM Rubber | Weather and chemical resistance | Improved durability in harsh environments |

| Interior Components | Foamed Rubber Materials | Lightweight with cushioning properties | Enhanced comfort and reduced weight |

| Anti-Skid Mats | Nitrile Rubber | High friction surface | Improved safety in vehicles |

Innovative rubber solutions are transforming the aerospace industry. Advanced rubber materials enhance performance and safety in various applications. For instance, the use of silicone rubber in seals significantly reduces fuel leakage. According to a recent industry report, these seals can improve efficiency by up to 15%. This increase is crucial for reducing costs and emissions.

Another application involves rubber components in aircraft engines. High-temperature elastomers withstand extreme conditions, ensuring reliability. These materials must endure temperatures exceeding 200°C. However, the challenge lies in developing rubbers that can maintain properties over time. Testing shows that some current formulations degrade faster than expected.

Moreover, vibration-damping rubber mounts are essential in reducing noise within the cabin. Studies reveal that such components can lower overall noise levels by 30%. However, innovations sometimes require a trial-and-error approach. Engineers must continuously evaluate new compounds to find the balance between performance and durability in harsh aerospace environments. This ongoing process highlights the complexity of integrating rubber solutions in aircraft design.

In the realm of sustainable fashion, rubber material offers exciting possibilities. This versatile material can be repurposed into fabrics, creating durable and eco-friendly textiles. By utilizing waste rubber, manufacturers can reduce their environmental impact significantly. However, this process isn't flawless; the quality may vary. Sourcing reliable rubber is also a challenge.

Textile manufacturing can embrace circular economy principles by recycling old rubber items. Closed-loop systems can emerge, reducing textile waste. Still, there are practical hurdles. Recycling facilities may lack the capacity to handle rubber textiles effectively. Many consumers are unaware of these innovations. Awareness is crucial for widespread adoption.

Innovative rubber applications can provide unique textures and durability. Designs using rubber can be waterproof and resilient. Yet, there's a risk of over-reliance on synthetic materials. Balancing innovation with sustainability demands constant reflection. These challenges indicate a need for more research and collaboration. The journey toward sustainable rubber in textiles is ongoing.

This chart illustrates the best innovative applications of rubber material projected for 2026, showcasing various sectors where sustainable rubber innovations play a key role, contributing significantly to a circular economy in textile manufacturing.

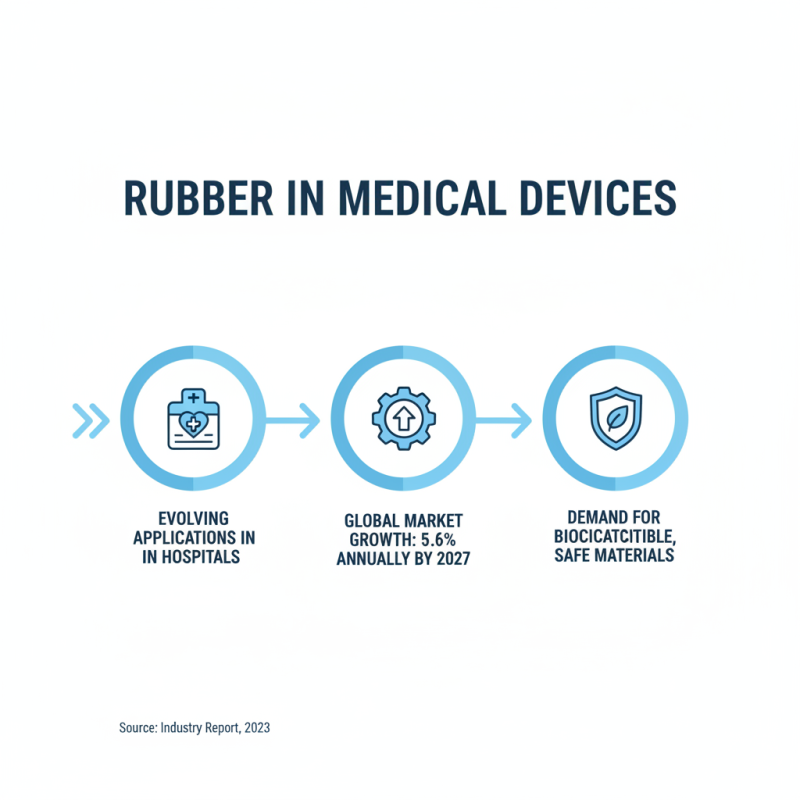

The applications of rubber in medical devices are continually evolving. Hospitals are increasingly using rubber-based materials due to their unique properties. A recent report highlights that the global rubber healthcare market is expected to grow by 5.6% annually until 2027. This growth stems from the demand for biocompatible materials that ensure patient safety.

Rubber is integral in devices like gloves, seals, and tubing. These products require reliability and durability. However, challenges remain. For instance, environmental concerns have arisen regarding rubber waste. Many facilities struggle with proper disposal. Additionally, not all rubber formulations meet strict medical standards. This raises questions about long-term use in sensitive medical environments.

Future trends indicate a shift towards synthetic rubber solutions. These materials can offer enhanced performance and reduce environmental impact. Yet, research is crucial to address potential allergies and reactions in patients. The industry must balance innovation with safety. Extracting maximum performance from rubber while minimizing drawbacks will be vital in this ongoing journey.